Coolant Filter Cleaning

The instrument cooling system has an inline filter which must be cleaned out periodically.

Indications

The INDI property instCool.status.flow_rate shows the instrument cooling flow rate in liters per minute. The pump speed

is shown in instCool.pump_level.current.

Coolant flow should be at or above 1.9 LPM under normal operating conditions. With the cameras off and with minimal computational loads it can fall below this due to the viscosity of cold glycol (especially at the telescope where it is colder than Tucson). If the system is under full load, the pump is on 10, and the sytem is in thermal equilibrium, but flow is consistenly under 1.9 LPM the filter should be inspected and cleaned if necessary. It should also be done routinely prior to a telescope run and every few months.

Note

the 1.9 LPM specification is derived from the required flow rate for the OCAM 2K camera (camwfs).

Precautions

Warning

Do not dump glycol down a sink drain or into the environment.

Warning

All liquid cooled components must be off prior to turning off instCool

Procedure

Required Tools

2x goose neck pliers

paper towels

a small flat screwdriver

wire brush

q-tip

acetone [maybe]

Initial Conditions.

RTC, ICC, and liquid cooled cameras (camwfs, camsci1, camsci2) off.

instCool on

3. Remove the lower cover plate labeld “cooling access” on the input side of the electronics rack to expose the cooler control panel.

Instrument cooling control panel access

4. Note coolant flow in instCool.status.flow_rate and on the cooler control panel. As noted above this is somewhat

thermal-load dependent.

Power off instCool with the rocker switch. Do this locally, as opposed to with pwrGUI, for later leak checks.

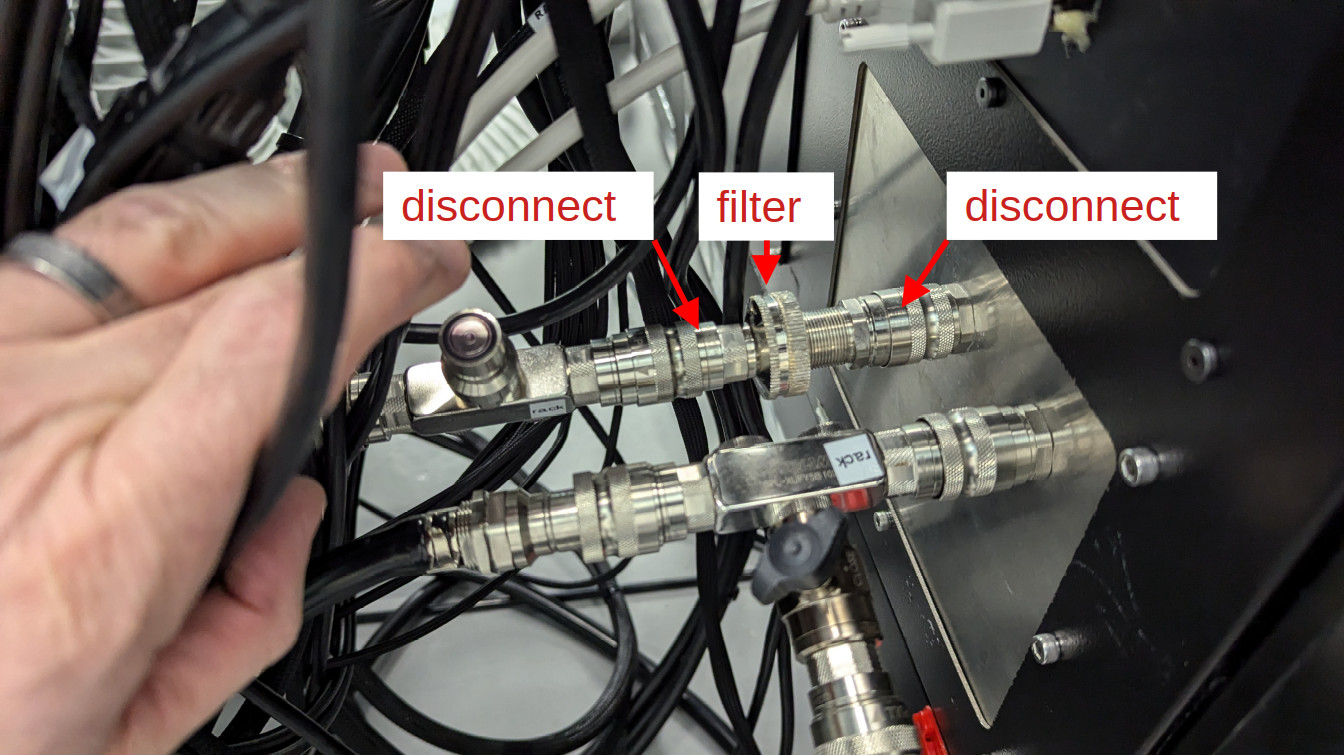

Remove the filter from the system using its quick disconnects.

Instrument cooling filter and quick disconnects.

Note

In the next step be sure to note the order of components inside the filter

Warning

Take care to not damage the o-rings

Using 2x goose neck plier (or a vise grip in a bench) open the filter housing by unscrewing it.

The red arrows indicate where the pliers grip to unscrew the filter housing.

After opening. The o-ring shown goes between the filter basket and the inside of the housing. The one shown is in need of replacement.

Remove the filter, being careful with the o-ring

The filter basket full of glycol gunk.

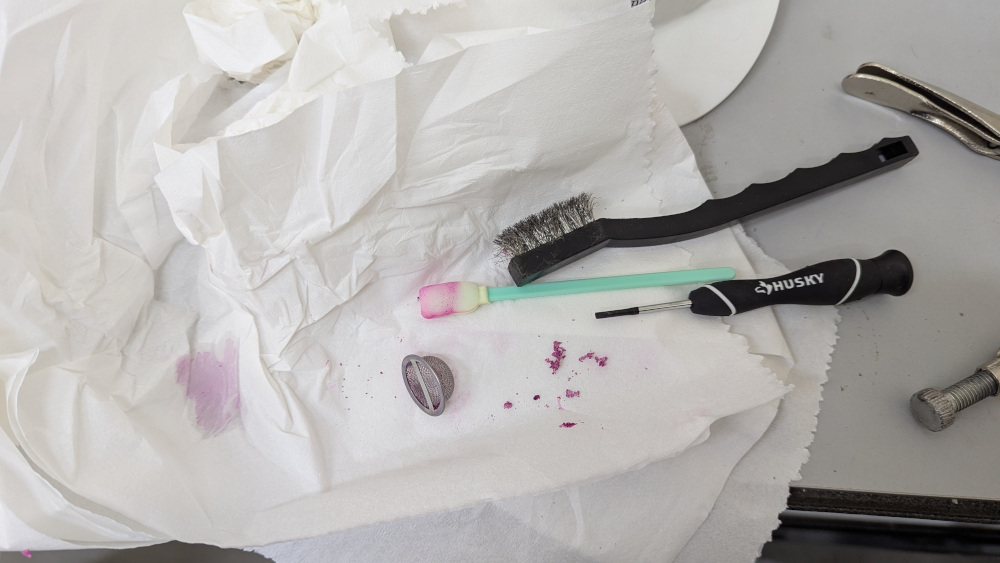

Clean the filter

Use the wire brush to dislodge the crud

Scrape with the screw driver as need inside

Soak in acetone if needed to loosen the crud

Once clean, rinse the filter in water to remove acetone residue

The filter basket after cleaning.

Reassemble the filter, carefully threading it together and seating on the o-ring.

Tighten with the pliers. Use full force, it should stop turning like it hit a hard stop.

Reinstall the filter.

Turn instCool back on with the rocker switch.

Check for leaks from the reinstalled filter (wait at least 10 minutes).

Note coolant flow, comparing to the pre-clean value noted above.

Reinstall the cover plate on the rack.

It is now ok to power up and do some wavefront control.