Coolant System Backflush

After a period of time (months), the glycol-based cooling system accumulates the byproduct of some kind of organism, maybe a type of slime mold, and the flow of glycol becomes restricted. This procedure should be done every 4-6 months to prevent high GPU and/or high CPU temps.

The filter basket needs to be cleaned before starting this procedure.

Procedure

Required Tools

2x CPU backflush jigs

2x GPU backflush jigs (smaller hose diam.)

paper towels

large flathead screwdriver (rack panel removal)

Initial Conditions.

RTC, ICC, and liquid cooled cameras (camwfs, camsci1, camsci2) off.

instCool on.

filter basket has been cleaned and reinstalled.

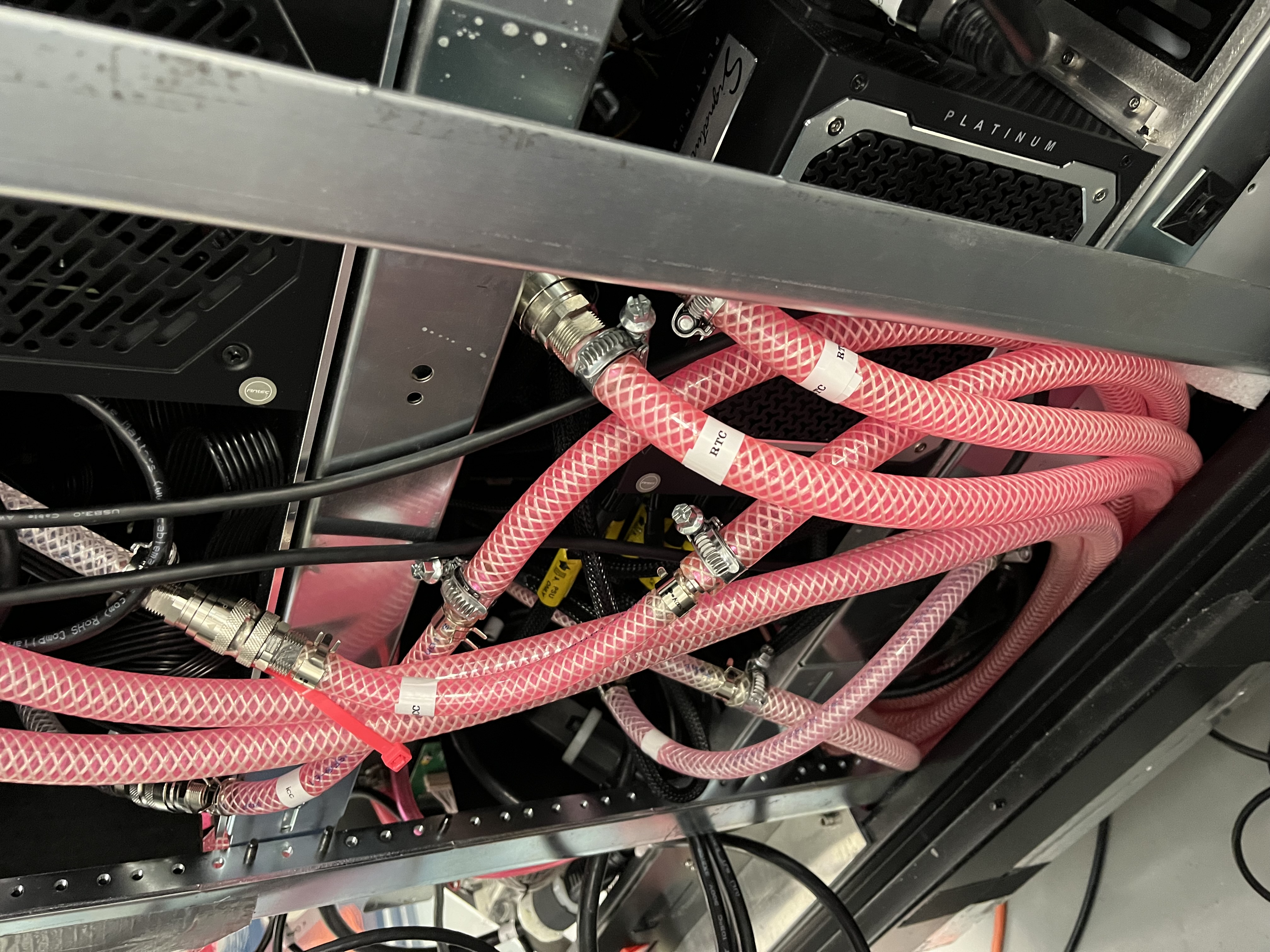

Disconnect the coolant hoses at the MagAO-X inlet and connect them together to form a closed loop. This is to maximize flow rate though the electronics rack.

4. Remove the large cover plate on the input side of the electronics rack (opposite to MagAO-X) to expose the cooler control panel.

View after removing the large input side cover plate

Note coolant flow in

instCool.status.flow_rateand on the cooler control panel. Make note of the initial average flow rate to gauge progress during the backflush.Power off instCool with the rocker switch. Do this locally, as opposed to with pwrGUI, for later leak checks.

Locate the hoses connected to each device to be backflushed. The GPUs are plumbed in series, so they must be backflushed one-by-one to avoid pushing large masses into the restrictive heat exchangers on each GPU.

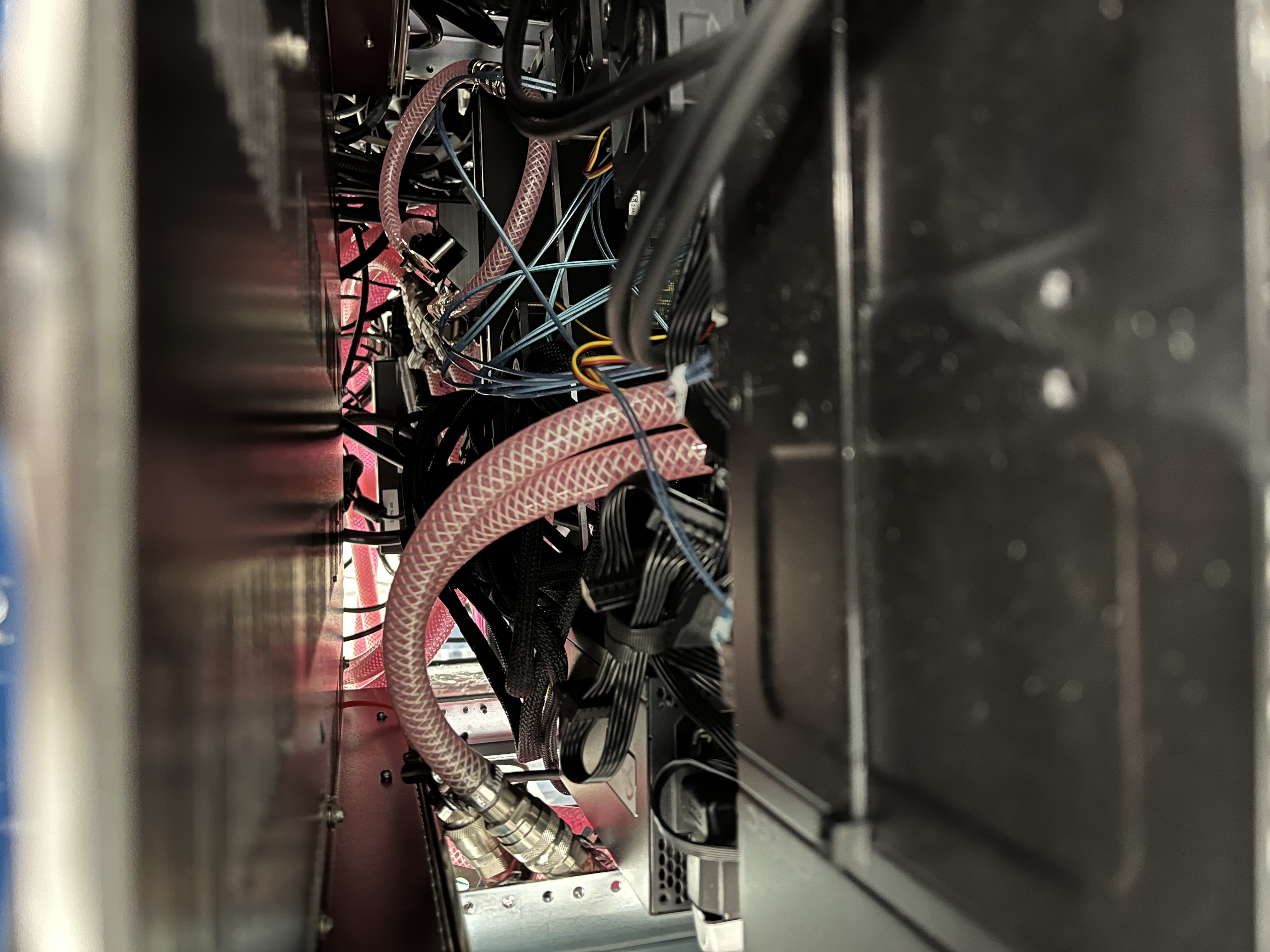

Example ICC CPU hose loop looking inside the rack from the front.

Warning

The quick-disconnects are well-engineered and normally leak-proof, but protect the instrument computers with paper towels under the hoses for good measure.

Disconnect both gpu and cpu coolant hoses, then connect each device hose individually and check the flow rate for each. Note if the flow rate is bouncing around, take the maximum.

Disconnect the two coolant hoses to one device and use the backflush jigs to reverse the flow of coolant to that specific device. Proceed with caution when backflushing the gpu and make sure you are connecting to the same gpu, or you will not get flow.

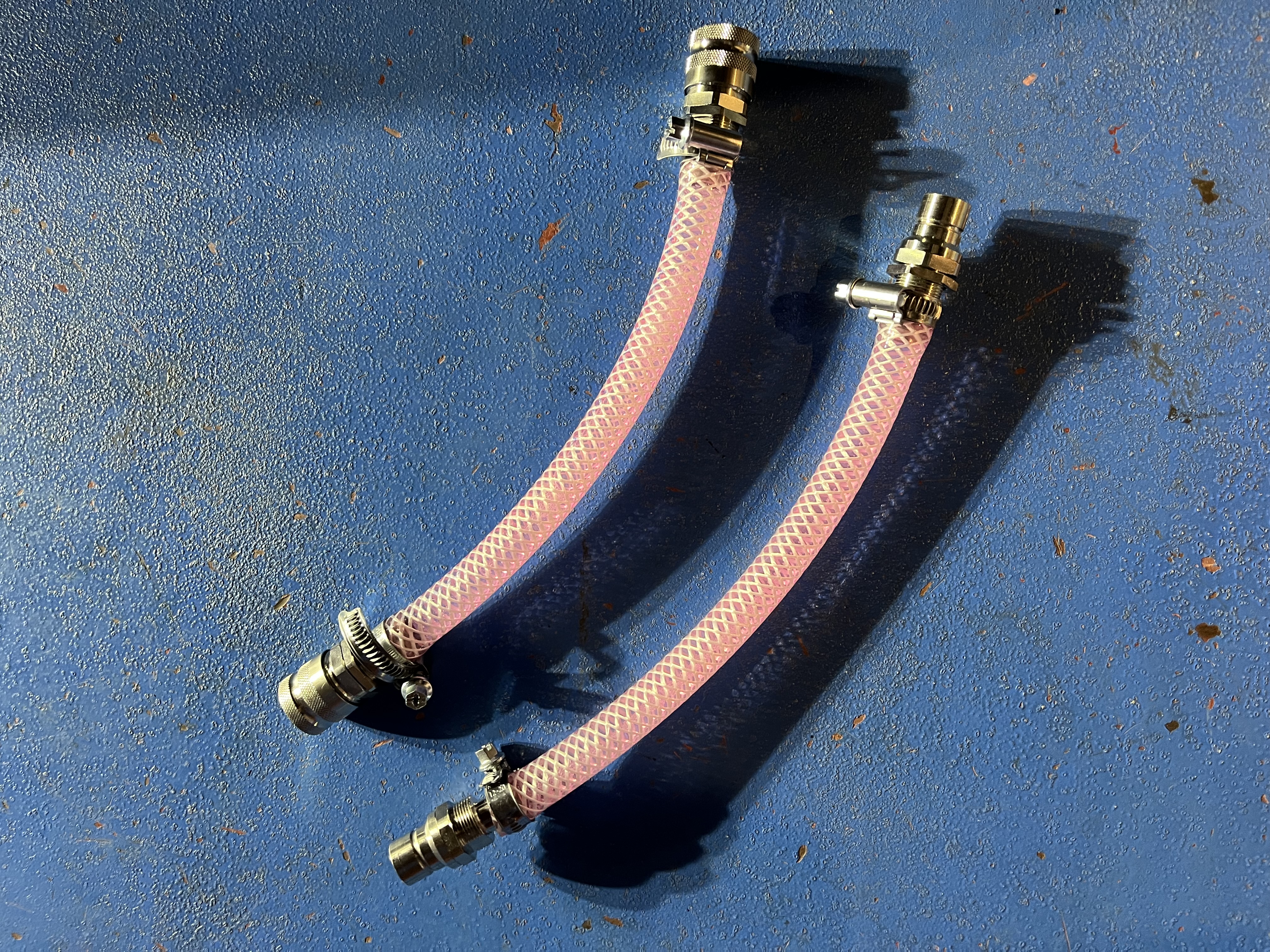

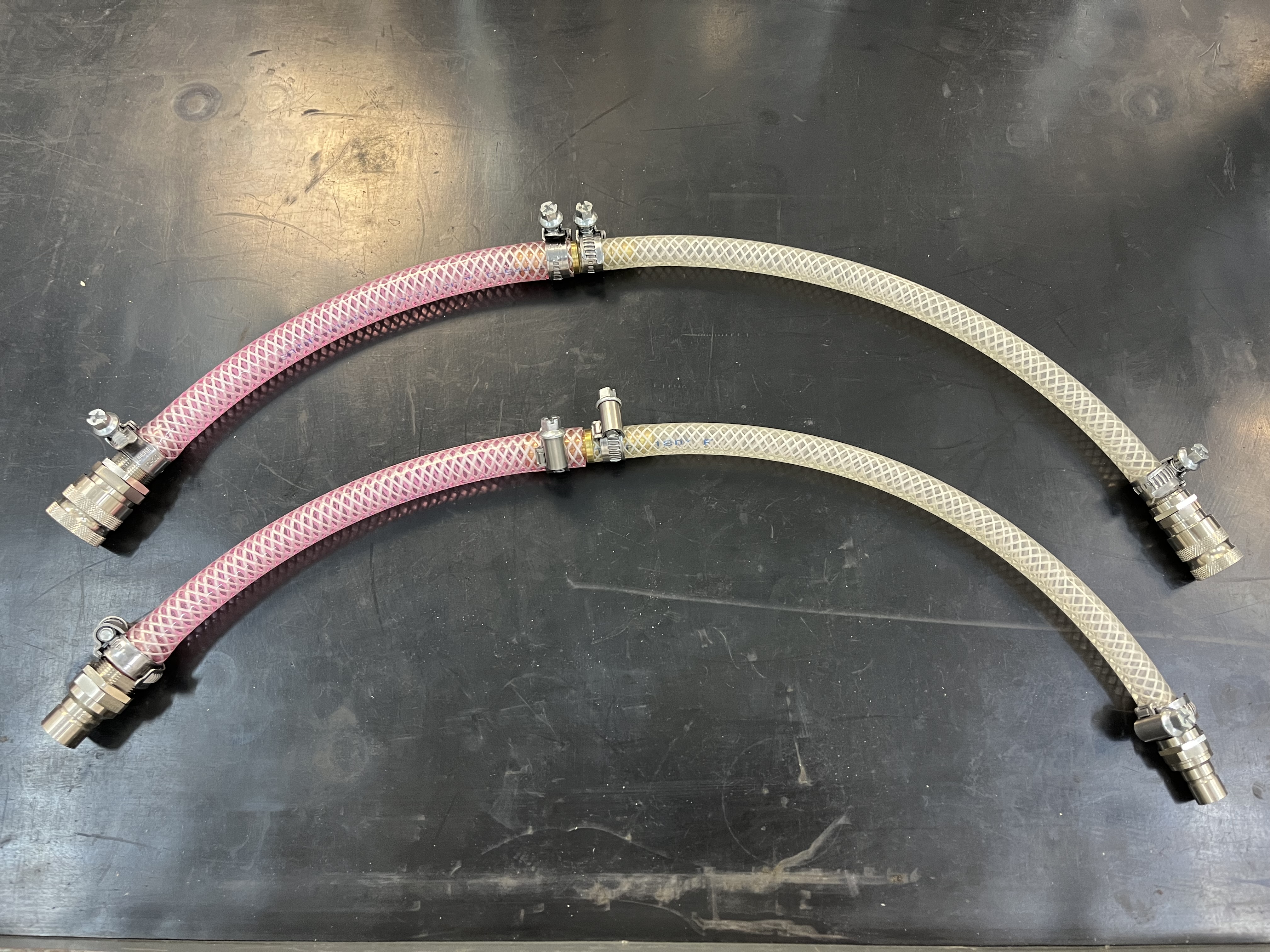

The jigs are composed of a male<->male and female<->female configuration for flow reversal.

The GPU hoses have a smaller diameter, so they require the jigs that feature a step down in connector size.

Power on instCool with the rocker switch and let the coolant flow for ~2 minutes. Make notes on the flow rate with

time. Power OFF :dev:`instCool`to lower cooling system pressure. Remove the jigs and reconnect the rack coolant hoses to restore the nominal configuration.

Flow rate should improve after a minute or so of backflushing.

Repeat steps 9 and 10 for each device that needs backflushing.

After backflushing, double check each hose connection for leaks when instCool is ON.

The filter basket needs to be cleaned after the backflushing procedure as per the guide.

The filter -will- be clogged after backflushing, ensure that it’s clean before returning to normal ops.

Finish up by reinstalling the input-side cover plate on the electronics rack and reconnecting the coolant hoses at the MagAO-X inlet.

Leak Check

The job is done when instCool is powered back on and all external connections are showing no leaks.