Installing MagAO-X on the Telescope

This procedure describes how to install the MagAO-X instrument on the Magellan Clay Telescope.

Estimated Time to Complete: 5 hours

This document can be downloaded as a PDF: Installing MagAO-X on the Telescope

Advanced Preparations

At least 1 week before the removal date, communicate with the LCO staff to arrange for the following:

Flatbed truck

crane scale (> 2000 lbs)

come-along

4 ratchet straps

Clay jib crane at 3 hairs speed

N2 bottle with regulator and quick-disconnect fitting on the platform

Initial Conditions

Instrument in LCO cleanroom on legs

Preparations

If operating, shut down MagAO-X.

Make sure to leave stages/wheels in positions that are safe for transportation

See complete procedure in the telescope removal procedure

Prepare Legs for Move

Turn off table legs (table air power off, PEPS II rocker switch off) and remove air connection from wall

Lie under table and remove all three (#1,2,& 3) geophones from bottom of table

Place coiled up geophones and cables into basket

Unplug PEPS II power from side of rack

Remove the taped down exhaust line from the clean room floor

Remove all cables

See detailed procedure for removing 2K DM cables

Electronics Rack

Ensure that roll-out shelves are restrained

If not installed, install side panels

Close and lock doors

Tape keys down

Instrument

remove polarimeter

install window cover

Remove eyepiece

Turn off blower, and remove hose

Tape over any exposed holes (from cables, etc)

Secure any loose cables

Shrink wrap the instrument

Install solar blanked over shrink wrap

Cart and Rigging

Verify all cart hardware is in-hand

Verify two wire harnesses are in hand

Partially assemble cart, leaving one long side off

Store cart out of the way so table can roll into unpacking area

Dome

The NASE platform shoud be clear and ready for MagAO-X installation

The dome jib crane should be set to “3 hairs” speed

XKID

If XKID is pre-cooling on the platform:

move the electronics to the dome floor

move the dewar to the corner of the platform

ensure cables are routed to minimize interference

Rig Onto Cart

Lower table legs onto the casters by turning the 16 leveling bolts, and remove the 12 metal pads

Roll the instrument out of the cleanroom

NOTE: At least 4 people required, 2 to push, 2 to hold the cleanroom sides open. Additional people are recommended to help guide.

CAUTION: only push on the legs, not the table itself

Continue rolling the instrument through the garage door into the unpacking area

Move the cart, currently with 3 sides, around the legs

CAUTION: be careful to not bump the legs with the cart

Attach the 4th side of the cart

Ensure that the 8 large bolts on the cart are snug but not tight

Attach the lifting wire-harness to each side of the cart. The hooks should point outward.

Attach the load spreader with straight extensions to the crane, using a crane scale (note this must be the heavy scale (>2000lbs))

The load spreader attached to the crane for lifting the cart

Place the load spreader in the center position (the cart is symmetric)

Lift the load spreader, and position it over the instrument

Being careful to not bump the instrument, lower the load spreader and attach the lifting harness D rings. Use 4x shackles to extend the length to reach the cart on the floor.

Lifting harnesses attached with shackle extensions

Position a person to hold each of the cart handles

CAUTION: Do not allow the cart to bump the legs or the table uncontrolled

Slowly lift the cart (320 lbs) until it is touching the bottom of the table.

The cart being lifted to the bottom of the table. Note the direction of the hooks.

Install the 4 outboard bolts. Loosen bolts on the cart as needed.

Once the cart is bolted to the table bottom, while 320 lbs is still on the crane, tighten all cart bolts. Do not over-tighten, make 1/4 turn after the washers are no longer free. This is to avoid excessive stress on the table.

Reposition the load spreader center to the instrument + cart position marked on it.

- CAUTION: be sure that the load spreader does not hit the cart when

being repositioned.

Install the triangle stabilizing ropes between the crane hook and the lifting fixture IAW the below figure. Tighten, but do not cause them to pick the load.

The triangle stabilizing ropes should be tight, but not become the lifting point for the load.

Ensure that there is room to move the legs out from under the table, opening the garage door into the cleanroom if necessary.

Position a person at each of the cart handles to stabilize it during the lift.

Position two people to remove the legs from under the table

Begin SLOWLY lifting the table off the legs. Once table is fully supported by the crane, the scale will read around 2000 lbs (as of March 2024).

Go up 0.5inch then stop and inspect the platters. Use a long flathead screwdriver to very gently pry any stuck platters off bottom of table.

Move the legs out from under the table.

The cart and instrument ready to be set down on the wheels, with legs out of the way.

Set the cart down on its wheels.

Re-check the cart bolts. Tighten any that are loose to 1/4 turn past when the washers stop moving.

Transport MagAO-X To Clay

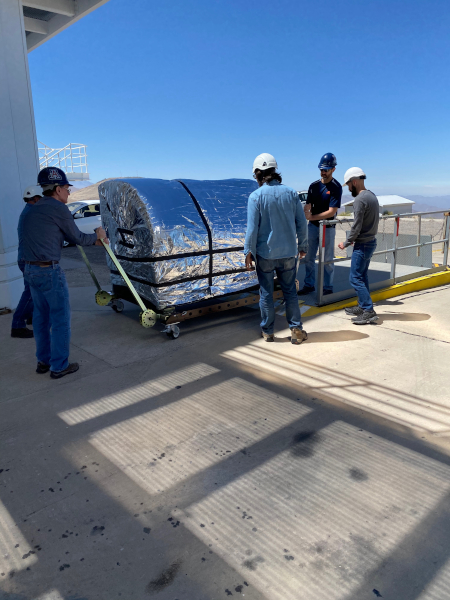

Move MagAO-X onto the lift gate (using plates over the gap)

MagAO-X moved onto the pentalift. Note the metal plates across the gap.

Raise the lift-gate to the height of the flatbed truck

Pentalift raised to truck height.

Place the plates across the gap.

Move MagAO-X onto the truck using the come-along

Secure the instrument by strapping the cart down at 4 points as illustrated in the below figure.

MagAO-X will be strapped to the Isuzu flatbed.

Slowly drive the truck to the summit.

Ensure that the lift gate at the summit has been adjusted for slow smooth operation as is done for the asm

Back the flatbed truck up to the lift gate.

MagAO-X will be unloaded at the telescope using the lift gate, adjusted for slow operation as it is for the ASM.

Next, using the come-along, carefully move MagAO-X onto the lift gate.

Use the come-along to move MagAO-X on the gate

Very slowly so as to minimize vibrations, move MagAO-X to the elevator, or place it in the Aux until ready to move to the elvator.

Slowly and carefully move MagAO-X to the telescop or Aux.

Moving the Legs to the Summit

Return to the cleanroom with the flatbed.

Placed on 2 dollies as in the below image.

Legs on 2 dollies placed in the middle of the table under each lower long tie bar (away from basket).

Move the legs to the flatbed and strap them down.

Legs strapped to the truck.

Slowly drive the truck to the summit.

Ensure that the lift gate at the summit has been adjusted for slow smooth operation downwards (slow air release) as is done for the ASM

Back the flatbed truck up to the lift gate.

Next carefully roll legs onto the lift gate.

Remove dollies from legs before going into elevator.

Bring the load spreader and rigging up with the legs.

Install MagAO-X On The Platform

Ensure the dome jib crane is set to “3 hairs” speed

Position the telescope so that the elevator has access to the NASE platform

Put MagAO-X on the NASE platform

Put the legs on the elevator and raise it the platform

Set the alignment pin system on the legs for receiving the instrument, and ensure that the platters are centered on the legs.

Attach the load spreader using the wire harnesses as above

Install the triangle stabilizing ropes

Position a person at each corner of the instrument to stabilize it

Lift the instrument with cart until it will clear the legs

Move the legs under the instrument.

Ensure that the table pads are centered

While keeping the instrument level, very slowly lower it into position using the alignment pins.

If one side touches first platters will move and repeat last few steps until platters are centered and pins are centered

Once on the legs, unload the crane to the cart weight of 320 lbs and re-position the load spreader for the cart

Adjusting the load spreader for the cart.

With the crane supporting the cart weight, remove the 4 bolts attaching the cart to the table

Lower the cart to the floor, and detach from the crane.

Stow the crane and handling gear

Remove the long side of the cart on the telescope side (4 bolts), and wheel the remaining pieces out from under table. Reassemble the cart and remove to the Aux. Bldg.

Conduct the daytime alignment procedure per alignment plan

See detailed alignment procedure Aligning MagAO-X to the Telescope

Transport Electronics

remove the earthquake bar

Use the lift gate to move the electronics rack onto a truck (either the flatbed or a pickup)

place foam between the rack side and the truck to protect cable connectors

The electronics rack has many delicate connectors on the side.

strap the rack securely to the truck using the D-rings (do not compresss the foam on the top with straps)

The rack on a truck for transport.

drive the truck to the summit

unload the rack using the lift gate, and move to the platform on the elevator

Install Electronics and Cable

- If needed, unplug from UPS power outlet to free up sockets:

MIKE CCD controller

telescope’s ADC (after retracting)

others’ fiber media converter

Place the rack in position next to the instrument. Leave enough room behind it so that the door can open.

Install the earthquake roll bar

lock the wheels

Check that the rack is stable and will not roll

Install all cables but the 2K DM cables

Power on the UPS located in the electronics rack

Install AOC in Control Room

Move the AOC, monitors and stand to the Clay control room

Connect AOC to the telescope 200 network, and to the “VisAO” port for the internal 192 network.

Connect the “VisAO” cable behind the MagAO rack in the equipment room directly to the media converter for VisAO.

On the platform connect the instrument lan to the VisAO fiber with a media converter

Power on the AOC

Conduct function checks of everything but the 2K DM

Cable the 2K

Cable the 2K DM following procedure

See MagAO-X PSR Document 2.2 Deformable Mirrors

Check actuator functionality, following this notebook on the RTC